- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

How to choose a check valve correctly?

In various industrial fluid systems, check valves are key components to prevent the backflow of media and are widely used in water supply and drainage, petrochemical, electric power, metallurgy and other industries. Although the check valve seems simple in structure, in actual selection, if the working conditions, installation location or medium characteristics are ignored, it is easy to cause operating failures or even system damage.

For corporate procurement personnel, accurately understanding the working principle and selection points of the check valve can not only increase the service life of the equipment, but also effectively reduce the subsequent maintenance costs. The following will explain how to scientifically select a suitable check valve from several core aspects.

1. Clarify the application conditions

The first step in selecting a check valve is to understand the basic parameters of the medium. Including:

Fluid type (clean water, oil, steam, corrosive liquid, etc.)

Medium temperature (low temperature, medium temperature or high temperature)

Working pressure (whether it is a high pressure system)

Whether it contains solid particles (such as sewage, mud system)

Different working conditions have different requirements for the structure and material of the check valve. For example, in high temperature and high pressure systems, rubber seals should be avoided, and metal seal check valves should be given priority.

2.Choose the appropriate structure type

Check valves can be mainly divided into the following types according to their structure:

Lift check valve: suitable for installation in horizontal pipes, suitable for occasions with high flow rate and frequent opening and closing. The structure is compact, but the installation direction is strict.

Swing check valve: high opening sensitivity, small pressure loss, suitable for medium and low pressure large diameter pipes.

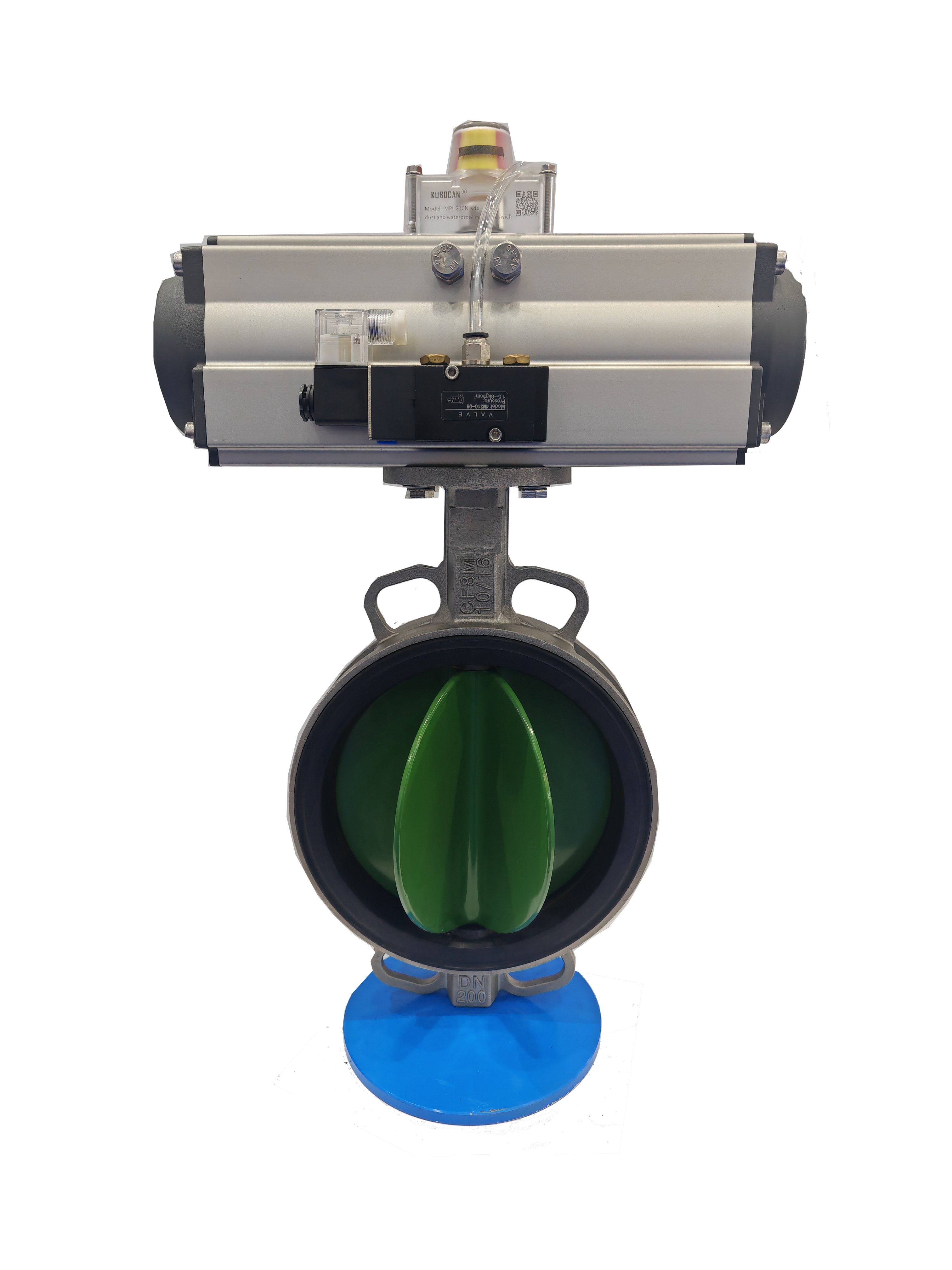

Butterfly check valve: small size, light weight, mostly used in systems with requirements for installation space, such as building water supply pipes.

Ball check valve: Suitable for pipes containing particles or viscous media, which can effectively prevent blockage.

Check valve combination pump set: Designed specifically for water pumps, it can reduce the impact of water hammer on the system.

When purchasing, you should choose a type with a reasonable structure based on the system pressure, installation space and medium characteristics.

3.Pay attention to materials and sealing performance

The main materials of check valves usually include cast iron, carbon steel, stainless steel, bronze, etc. When selecting, you must consider its corrosion resistance, temperature resistance and strength:

Ordinary water systems often use cast iron or bronze

Corrosive liquids can use stainless steel

Carbon steel or alloy steel structure is recommended for high pressure and high temperature conditions

In addition, the sealing surface material of the check valve directly affects the sealing performance and service life. Soft seals are suitable for clean media at room temperature, while metal seals are suitable for high temperature or impurity conditions

4.Confirm the installation direction and space conditions

Check valves usually have strict requirements on the installation direction. Incorrect installation will cause the valve to fail to open and close normally. The following points should be understood when purchasing:

Is there enough space to install the valve body

Does the pipeline direction allow the selection of a specific type (such as the lifting type can only be installed horizontally)

Is it convenient for future inspection and maintenance

If space is limited, vertical or wafer-type check valves can be given priority

5. Considering both economy and brand assurance

Although the check valve is a small component, once a failure occurs, it may cause system reflux, equipment damage or even shutdown. Therefore, when purchasing, you cannot just look at the price. The following points should be focused on:

Whether the product has passed the quality inspection

Whether the supplier provides after-sales technical support

Whether the valve life and maintenance convenience meet expectations

Choosing a valve manufacturer with stable supply capacity and technical support will greatly reduce the risk of later project operations.

When purchasing check valves, it is more important to choose and buy the right one

The selection of check valves seems simple, but it actually involves many aspects of technical judgment. For corporate purchasers, understanding its structural type, application scenarios, and material performance is the first step to ensure the stable operation of the system. It is recommended to fully communicate with engineers during the selection stage, and if necessary, contact the manufacturer to provide sample parameters or selection suggestions.

We have been focusing on industrial valve solutions for many years, and our products cover various types of check valves, supporting customization, technical guidance and installation services. If you have any questions during the selection process, please feel free to contact us.

Related News

- Why can ball valves be opened and closed quickly?

- What are the requirements for installing ball valves?

- Is there a strict requirement for the installation direction of ball valves?

- Can check valves prevent pump reversal

- What scenarios are check valves suitable for?

- What should I do if the check valve cannot stop the water?

Leave me a message

New Products