- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

What is the reason for frequent leakage of butterfly valves?

Analysis of the Reasons for Frequent Leakage of Butterfly Valves

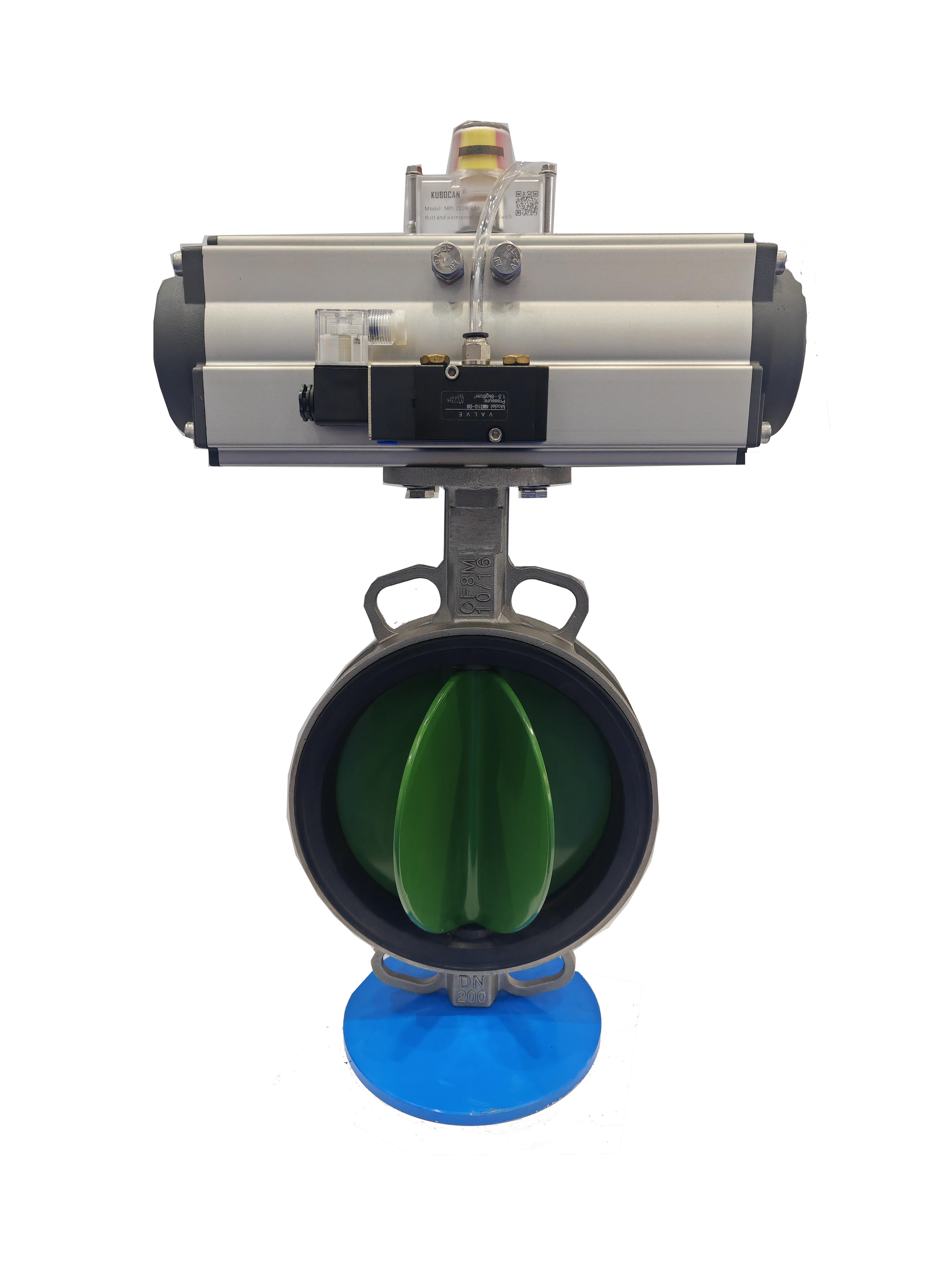

Butterfly valves, as a commonly used fluid control equipment, are widely used in many industrial fields. However, in actual use, butterfly valves frequently experience leakage problems, which not only affect production efficiency but may also pose safety hazards. The following analyzes the reasons for frequent leakage of butterfly valves from multiple perspectives.

Sealing structure issue

The sealing structure is a key part of butterfly valves to prevent leakage. If the material selection of the sealing ring is improper, it will not be able to adapt to different working conditions. For example, in high-temperature environments, if a sealing ring with poor temperature resistance is used, it will accelerate aging, harden, lose elasticity, resulting in poor sealing and leakage. In addition, the installation process of the sealing ring is also crucial. If the sealing ring is not evenly attached to the valve seat during installation, resulting in twisting, wrinkling, etc., then effective sealing cannot be formed when the valve is closed, and the medium will leak out from the gap. Moreover, as the usage time increases, the sealing ring will wear out due to frequent friction. When the wear reaches a certain level, the sealing performance will significantly decrease, and leakage phenomena will occur frequently.

Valve body and seat issues

The machining accuracy of the valve body and seat has a direct impact on the sealing performance of butterfly valves. If the surface roughness of the valve body and seat does not meet the requirements and there are defects such as scratches and dents, the sealing ring will not be able to tightly fit them when the valve is closed, resulting in a leakage channel. In addition, excessive coaxiality deviation between the valve body and valve seat can also lead to uneven stress on the sealing ring, with one side of the seal being too tight and the other side being too loose, making the loose side prone to leakage. During long-term use, the valve body and seat may also deform due to corrosion of the medium, further damaging the sealing performance and exacerbating the leakage problem.

Improper operation and maintenance

Incorrect operation is one of the common causes of butterfly valve leakage. For example, when opening or closing a butterfly valve, excessive or fast operating force can cause severe collision between the valve disc and the valve seat, resulting in damage to the sealing surface and causing leakage. Moreover, frequent opening and closing of butterfly valves can accelerate the wear of sealing rings and valve seats, shorten their service life, and increase the possibility of leakage. In terms of maintenance, if maintenance is not carried out for a long time, a large amount of impurities and dirt will accumulate inside the butterfly valve, which will get stuck between the sealing surfaces and affect the sealing effect. At the same time, the lack of regular lubrication and maintenance can cause the valve stem and other moving parts to rotate flexibly, increase operational resistance, and also easily lead to poor sealing.

Frequent leakage of butterfly valves is the result of multiple factors such as sealing structure, valve body and seat, and operation and maintenance. In order to reduce the occurrence of butterfly valve leakage problems, it is necessary to strictly control all aspects such as selection, installation, operation, and maintenance to ensure that the butterfly valve can operate normally and play its due role.

Related News

- Why can ball valves be opened and closed quickly?

- What are the requirements for installing ball valves?

- Is there a strict requirement for the installation direction of ball valves?

- Can check valves prevent pump reversal

- What scenarios are check valves suitable for?

- What should I do if the check valve cannot stop the water?

Leave me a message

New Products