- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

What are the classifications of check valves?

As a key equipment to prevent medium backflow, check valves are widely used in pipeline systems. According to different structures and working principles, check valves are mainly divided into the following categories:

1. Swing check valve

The rotary check valve opens and closes by rotating the valve disc around a fixed axis. When the medium flows forward, the valve disc is pushed open; When reversing, the valve disc closes under its own weight and the reaction force of the medium. Its advantages are low flow resistance, rapid opening and closing, suitable for large-diameter, low flow rate scenarios such as pump outlets or horizontal pipelines. However, water hammer effect may occur during high-speed flow, and a buffer device is required.

2. Lift check valve

The valve disc of the lift check valve moves along the vertical axis of the valve body. When flowing forward, the medium pressure pushes the valve disc up; When reversing, the valve disc falls under the action of gravity or spring force, cutting off the medium. This type of check valve has good sealing performance, but high flow resistance, and is mostly used in small caliber, high-pressure, or vertically installed applications, such as steam systems.

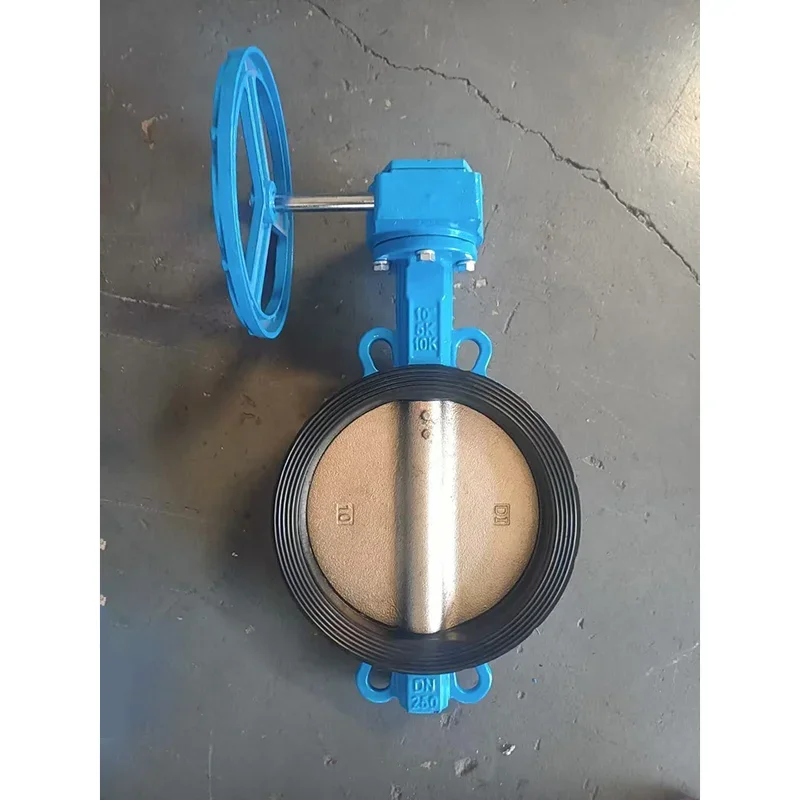

3. Butterfly check valve

Butterfly check valve combines the characteristics of rotary and butterfly valves, with a circular disc that rotates around the central axis. It has a compact structure and light weight, suitable for large-diameter and low-pressure pipelines, and is commonly used in water supply and drainage engineering. But the sealing is relatively weak and requires regular maintenance.

4. Diaphragm check valve

Diaphragm check valves use the elastic deformation of rubber diaphragms to control opening and closing. When the medium flows forward, the diaphragm is stretched open; When reversing, the diaphragm rebounds to seal the channel. This type of check valve has no mechanical friction and a long service life, but its temperature and pressure resistance are limited, and it is mostly used for cleaning media or low-pressure systems.

5. Piston check valve

The piston check valve opens and closes through the cooperation of the piston and spring. The medium pressure overcomes the spring force to push the piston to move, and the spring returns and closes when reversing. It has excellent sealing performance and is suitable for high temperature and high pressure environments, such as the petrochemical industry, but its structure is complex and the cost is high.

The applicable scenarios of different types of check valves need to be comprehensively selected based on the characteristics of the medium, pressure, flow rate, and installation conditions to ensure the safe and efficient operation of the system.

Previous :

Related News

- What are the requirements for installing ball valves?

- Is there a strict requirement for the installation direction of ball valves?

- Can check valves prevent pump reversal

- What scenarios are check valves suitable for?

- What should I do if the check valve cannot stop the water?

- What should I do if there is leakage inside the check valve

Leave me a message

New Products