- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

Why can ball valves be opened and closed quickly?

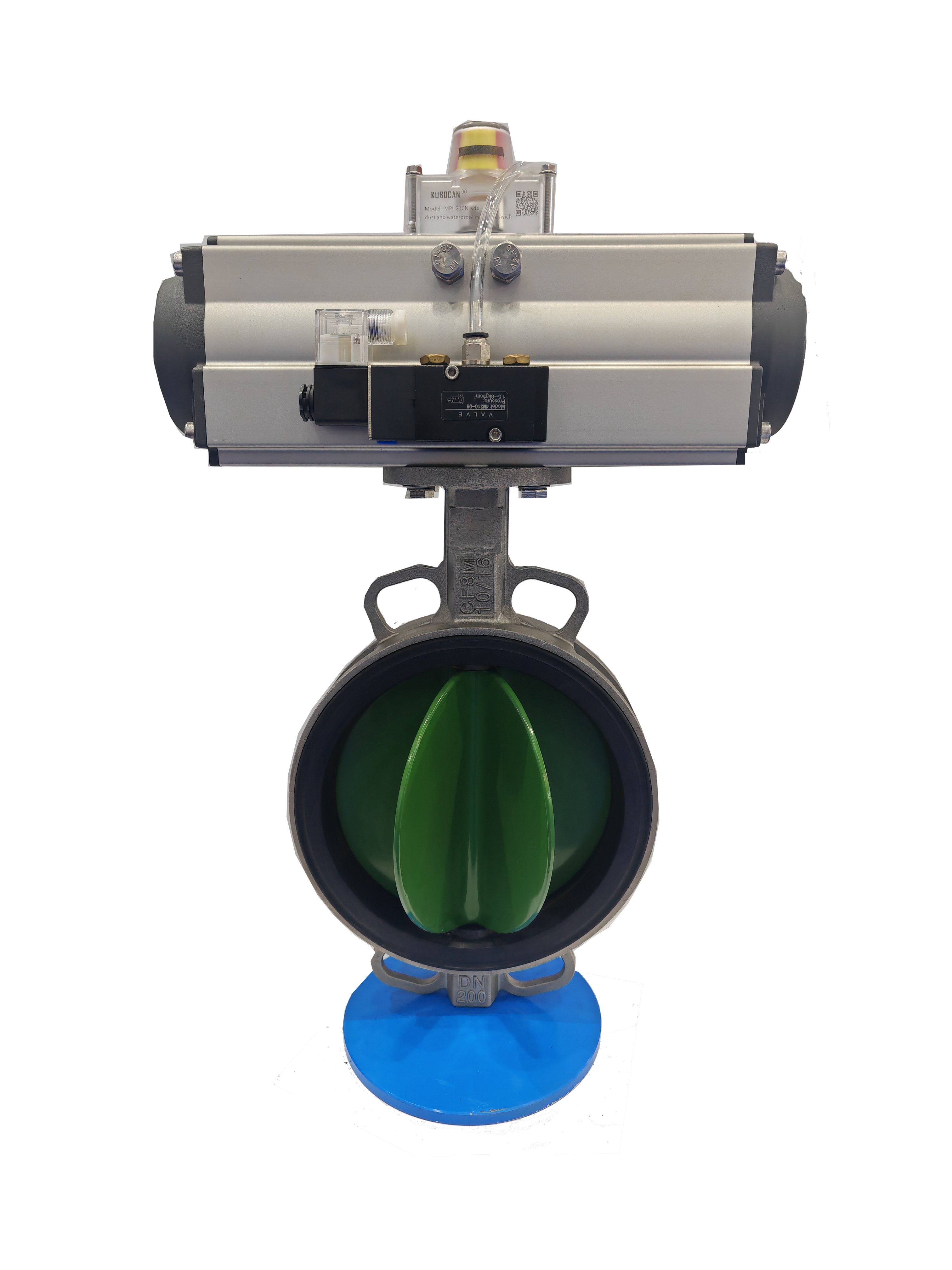

The reason why ball valves can achieve rapid opening and closing lies in their unique mechanical structure and fluid dynamics design. The opening and closing component is a sphere with a circular through-hole, which can be driven by the valve stem to rotate 90 degrees around its own axis to complete the state switch - when the through-hole of the sphere is aligned with the pipeline axis, the valve is fully opened; After rotating 90 degrees, the through-hole is perpendicular to the pipeline and the valve is fully closed. This "quarter turn" design simplifies the opening and closing action into a rotational motion within a single plane, greatly shortening the operating path.

From the perspective of mechanical structure, the ball of the ball valve adopts a "line contact" or "surface contact" sealing method with the valve seat. Taking a floating ball valve as an example, the ball will move towards the outlet valve seat under the pressure of the medium, forming a self tight seal and reducing the frictional resistance during opening and closing; The fixed ball valve is supported by the bearings of the upper and lower valve stems, so that the ball only needs to overcome the small frictional force between the valve seat and the ball when rotating. This design makes the sphere almost unaffected by fluid resistance during rotation, especially suitable for high-pressure conditions. For example, in the petrochemical industry, DN300 pneumatic ball valves can complete opening and closing in 0.5 seconds, much faster than gate valves or globe valves that require multiple rotations.

The fluid dynamics characteristics further enhance the fast response capability of the ball valve. The flow channel of the full bore ball valve is completely consistent with the inner diameter of the pipeline, and there is almost no pressure drop when the fluid passes through. There will be no additional resistance due to the inertia of the medium during opening and closing. In contrast, the butterfly valve's disc may obstruct some of the flow channels during rotation, causing the fluid to exert reverse thrust on the disc and affecting the opening and closing speed; The gate of the gate valve needs to be vertically raised and lowered, with a long stroke and is easily affected by the viscosity of the medium. Experimental data shows that in DN200 pipelines, the opening and closing time of ball valves is 40% shorter than that of butterfly valves of the same specification and 70% shorter than that of gate valves.

In addition, the driving method of the ball valve also provides support for its rapid opening and closing. Pneumatic, electric, or hydraulic actuators can instantly output high torque, driving the sphere to complete a 90 degree rotation within 0.1 seconds. For example, in a natural gas emergency shutdown system, a pneumatic ball valve can cut off the airflow within 0.3 seconds by receiving electrical signals, effectively preventing accidents from escalating. This "millisecond level" response capability is unmatched by traditional manual valves.

Next :

-

Related News

- What are the requirements for installing ball valves?

- Is there a strict requirement for the installation direction of ball valves?

- Can check valves prevent pump reversal

- What scenarios are check valves suitable for?

- What should I do if the check valve cannot stop the water?

- What should I do if there is leakage inside the check valve

Leave me a message

New Products