- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

What should I do if the valve seal was not good last time?

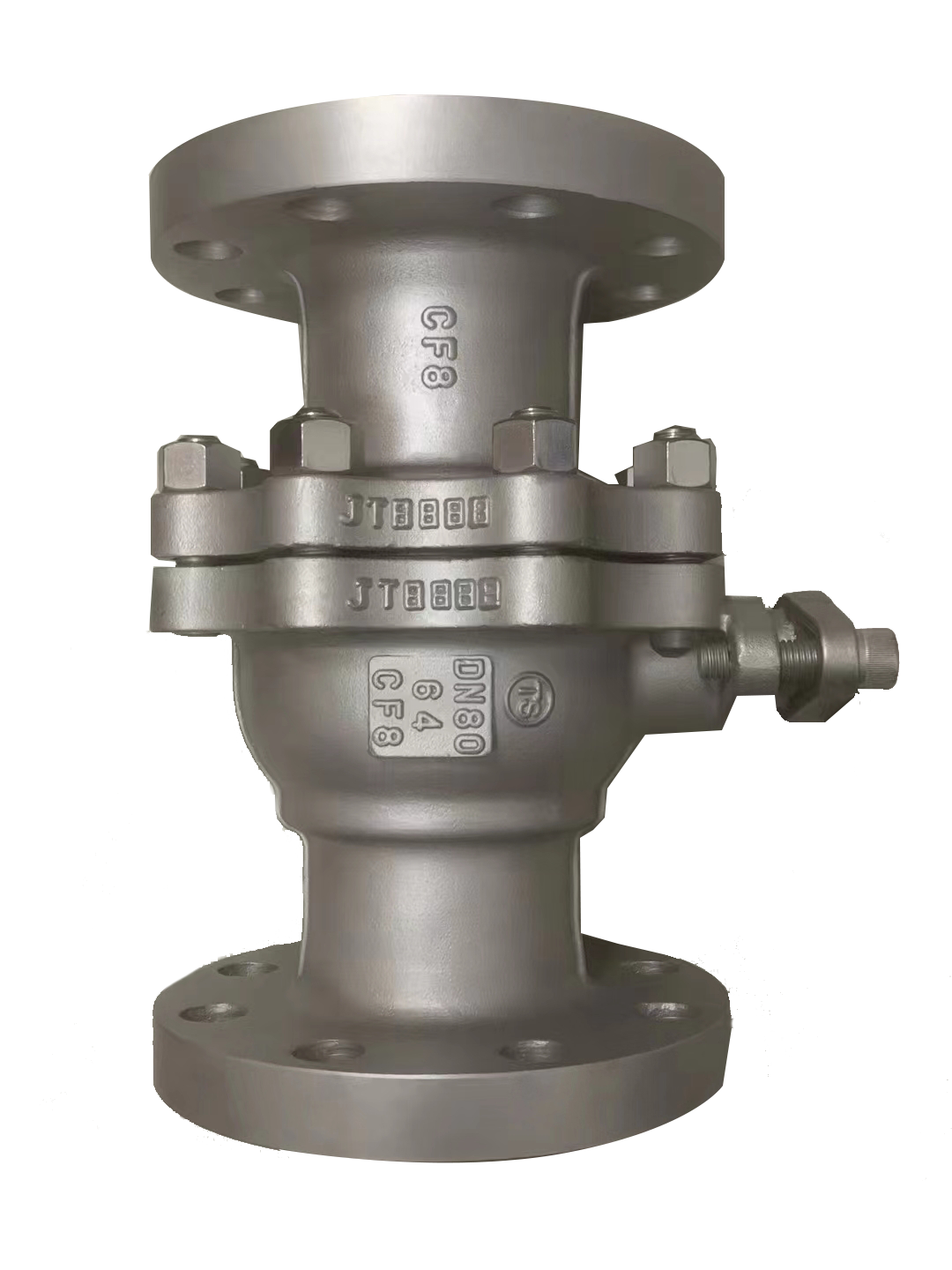

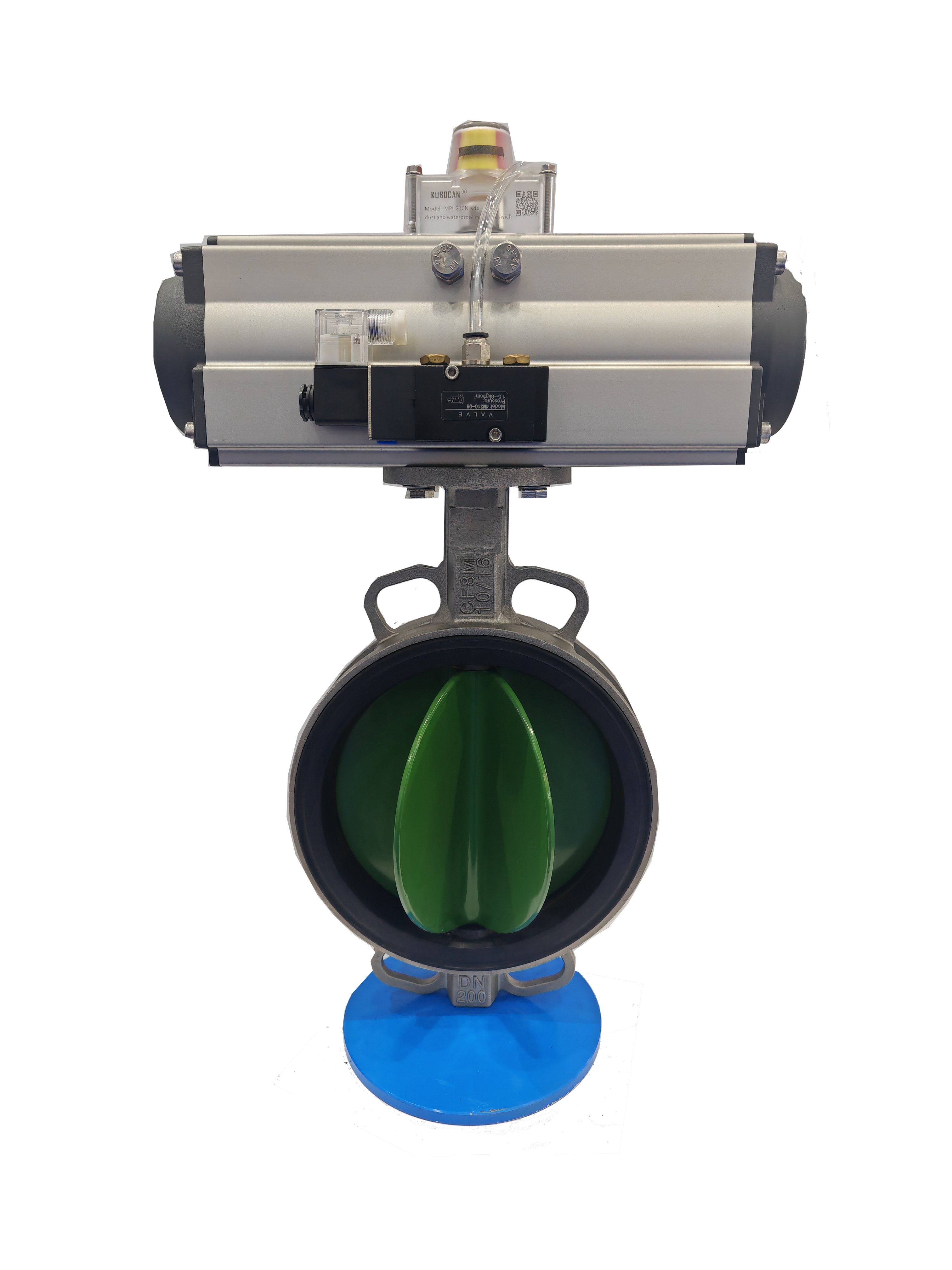

Is the check valve poorly sealed? These methods will help you get it done

Check valves play a crucial role in preventing medium backflow in pipeline systems. If their sealing is not good, it can cause various problems, such as water backflow and gas reflux, which can affect the normal operation of the system. Don't worry, here are some methods to solve the sealing problem of check valves.

Check the installation status

Improper installation of check valves is a common cause of poor sealing. Firstly, it is necessary to confirm whether the installation direction of the check valve is correct. Each type of check valve has a specified direction for the flow of the medium. If installed in the wrong direction, the medium cannot pass through normally, and thus good sealing cannot be achieved. Secondly, check if the check valve is installed vertically (some types require this), as tilting the installation may cause uneven force on the valve disc, affecting the sealing performance. In addition, check whether the pipeline connections are tight. If there are looseness or gaps, it may cause medium leakage and affect the sealing effect of the check valve. At this time, it is necessary to re tighten the connecting components.

Clean the debris inside the valve

Impurities in the pipeline, such as rust, sand particles, welding slag, etc., can easily get stuck between the valve disc and seat of the check valve, damaging the sealing surface and causing poor sealing. At this point, it is necessary to remove the check valve from the pipeline and carefully clean the debris on the valve disc and seat. Soft brushes or clean cloths can be used for wiping, and for stubborn stains, mild cleaning agents can be used appropriately, but care should be taken to avoid damaging the sealing surface. After cleaning, reinstall the check valve and check if the sealing condition has improved.

Replace the sealing element

If the check valve is used for a long time, the sealing components (such as gaskets, seals, etc.) may experience wear and aging, leading to a decrease in sealing performance. In this case, it is necessary to purchase sealing components that match the original check valve model for replacement. During the replacement process, it is important to ensure that the sealing components are installed correctly and smoothly, avoiding distortion or displacement, in order to ensure a good sealing effect.

If the sealing problem of the check valve is still not solved after the above methods are used, it is recommended to contact professional maintenance personnel or check valve manufacturers for more professional technical support and solutions.

Related News

- Is there a strict requirement for the installation direction of ball valves?

- Can check valves prevent pump reversal

- What scenarios are check valves suitable for?

- What should I do if the check valve cannot stop the water?

- What should I do if there is leakage inside the check valve

- What are the types of check valves

Leave me a message

New Products