- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

What happens if the butterfly valve is selected incorrectly?

2025-09-08

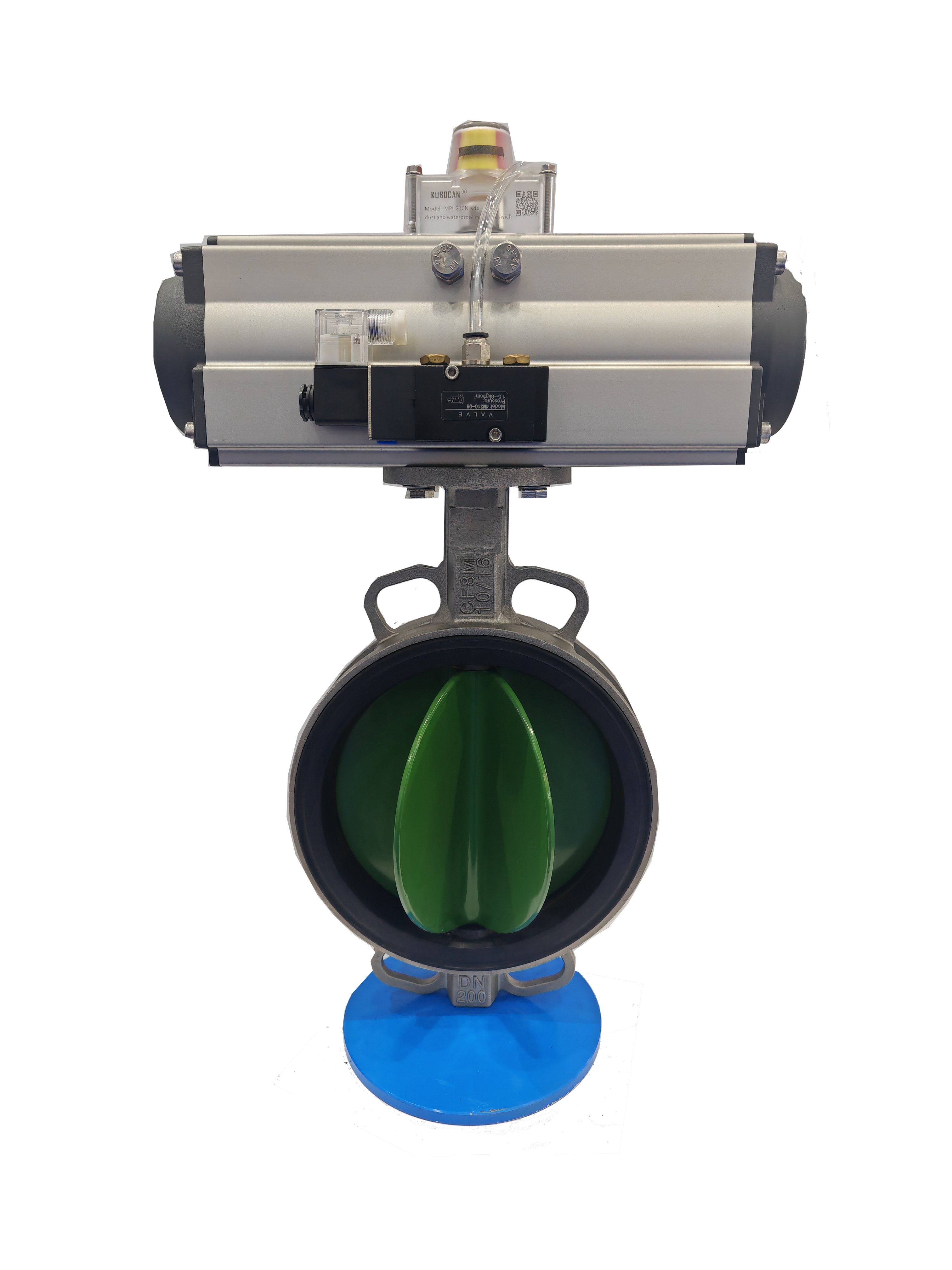

What happens if the butterfly valve is selected incorrectly?

In the fields of industrial production and fluid control, butterfly valves are extremely common key equipment, and the correct selection plays a decisive role in the stable operation of the system. Once the butterfly valve is selected incorrectly, it will cause a series of serious problems.

From a performance perspective, selecting the wrong butterfly valve can lead to a significant reduction in control accuracy. For example, in chemical production processes that require precise adjustment of fluid flow rate, if butterfly valves with inappropriate diameters or poor sealing performance are selected, it is impossible to accurately control the flow rate, resulting in unstable chemical reaction conditions, uneven product quality, and a significant increase in waste rate, which brings huge economic losses to the enterprise.

In terms of safety, unsuitable butterfly valves pose numerous hidden dangers. In some high-temperature, high-pressure, or corrosive media environments, if the material, pressure resistance, temperature resistance, and corrosion resistance of butterfly valves cannot meet the requirements, leakage problems are highly likely to occur. Minor leaks not only cause waste of media and increase production costs, but may also pollute the environment; Serious leaks may even lead to major safety accidents such as fires and explosions, threatening the lives of workers and the property safety of enterprises.

The service life can also be significantly shortened due to improper selection of butterfly valves. If the working pressure, temperature and other parameters of the butterfly valve exceed its design range, or if there are too many impurities in the medium and appropriate filtration and protection measures are not selected, the components of the butterfly valve will accelerate wear and aging, frequently fail, and require frequent maintenance and replacement. This not only increases maintenance costs, but also affects the continuity of production, resulting in low production efficiency.

In addition, selecting the wrong butterfly valve may also affect the compatibility of the entire system. Butterfly valves of different specifications and types have differences in connection and control methods. If the selection does not match the existing system, a large-scale renovation of the system is required, which increases the difficulty and cost of the project.

It can be seen that choosing the wrong butterfly valve can have serious consequences. When selecting, it is necessary to fully consider various factors such as the characteristics of the working medium, process parameters, and usage environment to ensure the selection of a suitable butterfly valve, in order to ensure the safe, stable, and efficient operation of the system.

Related News

- Are there any requirements for the installation direction of butterfly valves?

- How long is the service life of butterfly valves generally?

- What media environments are butterfly valves suitable for?

- What will happen to ball valves at low temperatures?

- What is the basis for achieving ball valve sealing?

- Why can ball valves open and close quickly?

New Products