- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

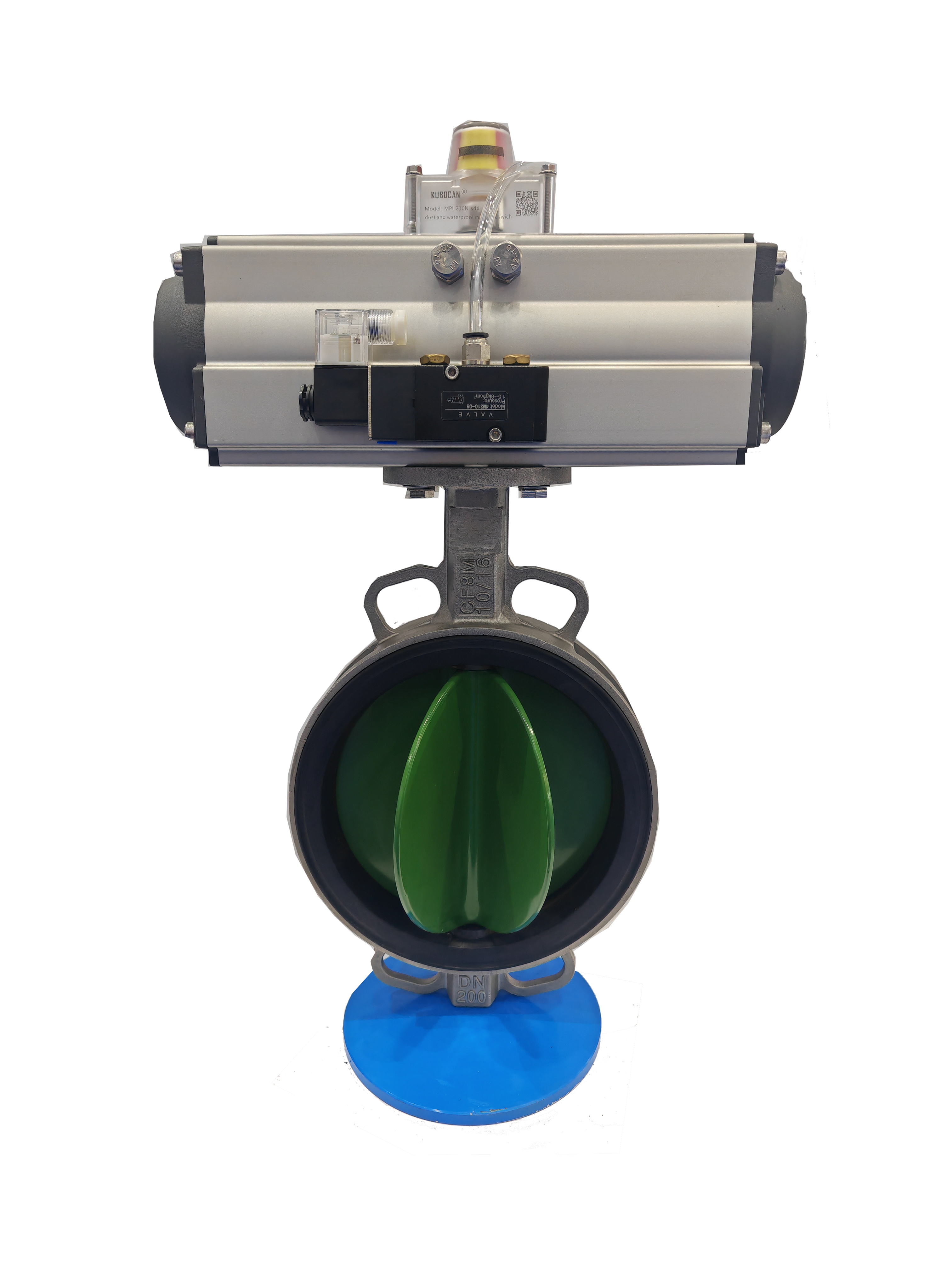

Are there any requirements for the installation direction of butterfly valves?

2025-12-04

The installation direction of butterfly valves should be determined according to their type and working conditions. Bidirectional sealed butterfly valves generally do not have strict directional requirements, but there are recommended installation directions; The one-way sealed butterfly valve must be installed in the direction indicated by the arrow, and the direction of the valve stem should avoid vertical downward to ensure safe operation and sealing performance.

Butterfly valves are divided into two types: bidirectional sealing and unidirectional sealing. For bidirectional sealed butterfly valves, theoretically there are no strict directional restrictions on installation, but there are recommended installation directions in practical engineering. For example, in a horizontal pipeline, the direction of the valve stem can be selected in the order of vertical upward, horizontal, and 45 ° upward inclination. This installation method is easy to operate and can ensure the uniformity of the seal. For large-diameter butterfly valves (such as DN500 and above), it is recommended to install the valve body horizontally and the actuator above to avoid the influence of the valve plate's own weight on torque. If the pipeline medium contains sediment (such as mud, sand, and water), it is recommended that the medium flow enters from the back side of the valve plate sealing surface to reduce wear and extend valve life.

The installation of one-way sealed butterfly valves has clear directional requirements. The valve body is usually marked with arrow markings, and the direction of the arrow must be consistent with the flow direction of the medium in the pipeline during installation, otherwise it may cause seal failure or medium leakage.

Both bidirectional and unidirectional butterfly valves are not allowed to be installed vertically downwards in the direction of the valve stem. If the valve stem is facing downwards, the pipeline medium may leak from the valve stem, especially when transporting acidic, alkaline, and toxic media, which poses a threat to the personal safety of operators. In addition, installing the valve stem downwards will increase the difficulty of operation, requiring the operator to lift their head for operation, which is not in line with ergonomic design.

The installation position of butterfly valves should be easy to operate. The handle or handwheel of manual butterfly valves is generally 1.2 meters away from the operating floor, about to the chest position, which makes opening and closing more effortless. If the valve is installed on the ground, the handwheel or handle should face upwards and not tilt; If installed against walls or equipment, leave standing space for operators to avoid working from the sky.

Next :

-

Related News

- How long is the service life of butterfly valves generally?

- What media environments are butterfly valves suitable for?

- What will happen to ball valves at low temperatures?

- What is the basis for achieving ball valve sealing?

- Why can ball valves open and close quickly?

- How to troubleshoot check valve faults?

New Products