- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

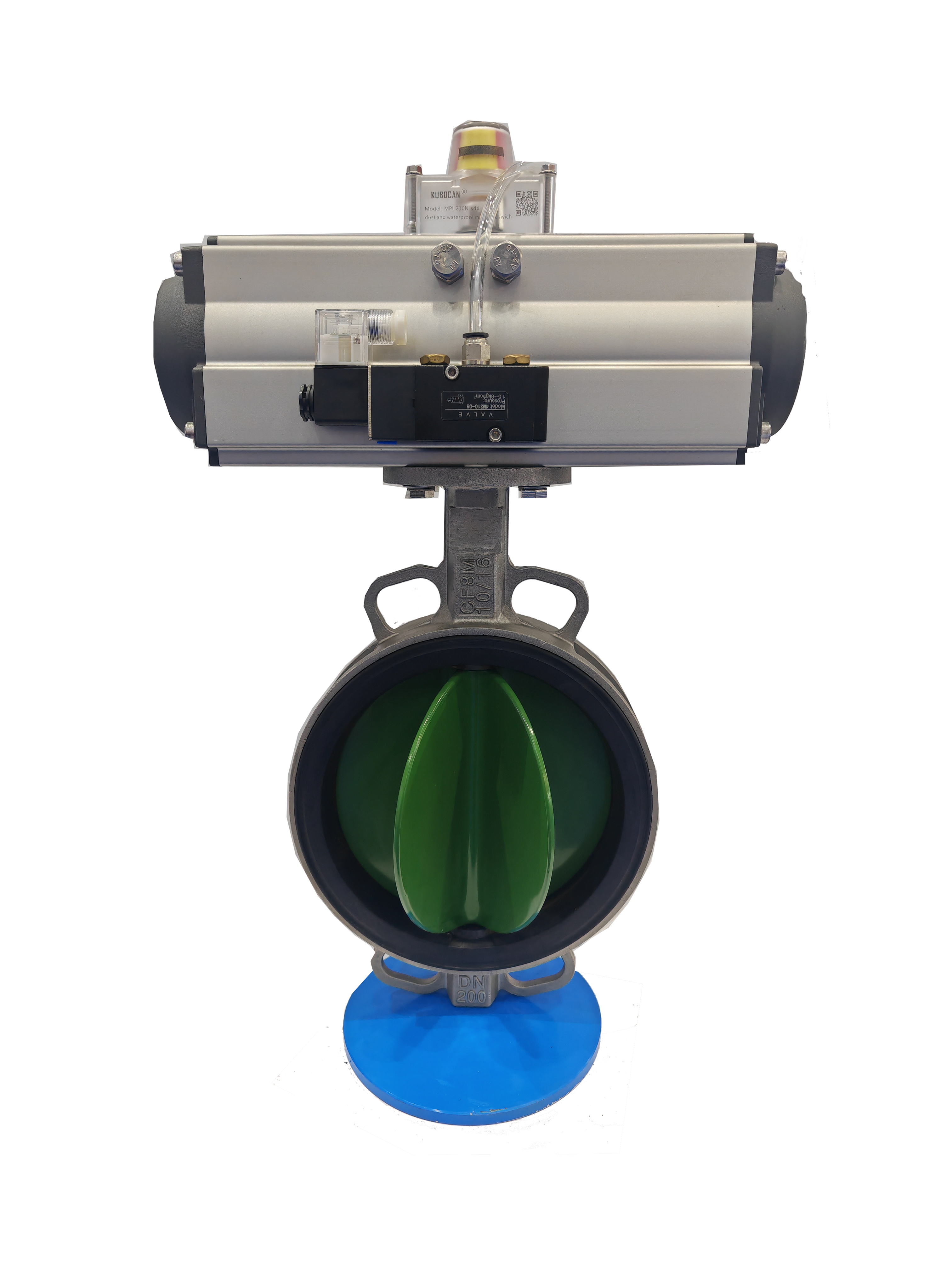

How long is the service life of butterfly valves generally?

2025-12-03

The service life of butterfly valves is affected by multiple intertwined factors, usually fluctuating within the range of 5 to 20 years.

Specific judgments need to be made based on the material, working conditions, operating frequency, and maintenance level. The difference in core lifespan is due to design differences in sealing structures: soft sealed butterfly valves rely on elastic materials such as rubber or polytetrafluoroethylene to achieve sealing. Although these materials have excellent sealing performance, they are prone to creep and aging when subjected to medium pressure, temperature changes, and frequent opening and closing, resulting in deformation or cracking of the sealing surface. For example, under normal temperature and clean water conditions, the soft sealed butterfly valve can be opened and closed more than 50000 times, with a lifespan of about 5 to 8 years; If used in a conveying system containing granular media, particle erosion will accelerate the wear of the sealing surface, and the service life may be shortened to 3 to 5 years. The hard sealed butterfly valve adopts metal to metal sealing (such as stainless steel, chromium molybdenum steel), and its wear resistance is improved by welding hard alloy or spraying wear-resistant coating. Its three eccentric structure achieves frictionless opening and closing process through three-dimensional offset of axis, cone surface and contact point, significantly reducing wear rate. In high-temperature and high-pressure steam pipelines, the opening and closing times of hard sealed butterfly valves can exceed 100000 times, and their lifespan can reach 10 to 20 years; If the medium is a highly corrosive chemical solution, corrosion-resistant materials such as Hastelloy should be used. Although the lifespan may be slightly shortened due to material cost limitations, it can still operate stably for 8 to 15 years.

Working conditions are another key factor determining the lifespan of butterfly valves. In clean media, mild environments, and low-frequency operating scenarios, valve components are subjected to uniform force, with low wear rates and a lifespan generally approaching the theoretical upper limit. For example, in urban water supply systems, soft sealed butterfly valves can be opened and closed less than 5 times a day, and with proper maintenance, their lifespan can reach 8 to 10 years. On the contrary, in harsh working conditions such as metallurgy and chemical engineering, high temperature (over 400 ℃), high pressure (over 10MPa), strong corrosion (such as acid-base solutions), or high wear (such as slurry and ash) media can accelerate material aging and structural damage. For example, in the blast furnace gas pipeline of a steel plant, the hard sealed butterfly valve needs to withstand the high temperature of 800 ℃ and the scouring of dusty airflow. Even with ceramic coating protection, its service life can only be maintained for 5 to 8 years.

The impact of operating habits and maintenance level on lifespan cannot be ignored. Frequent opening and closing (more than 10 times a day) can exacerbate wear on transmission components such as valve stems and bearings, leading to increased opening and closing torque and even jamming; Failure to maintain according to specifications (such as not regularly lubricating or cleaning impurities on the sealing surface) will accelerate the aging of the seals and shorten the overall lifespan of the valve. For example, in a chemical plant, the failure to regularly replace the valve seat sealing ring resulted in serious leakage of the valve after 3 years of operation, while a valve maintained in accordance with regulations under the same working conditions can have a lifespan of up to 12 years. Therefore, reasonable selection, standardized operation, and regular maintenance are the core strategies to extend the service life of butterfly valves.

Related News

- Are there any requirements for the installation direction of butterfly valves?

- What media environments are butterfly valves suitable for?

- What will happen to ball valves at low temperatures?

- What is the basis for achieving ball valve sealing?

- Why can ball valves open and close quickly?

- How to troubleshoot check valve faults?

New Products